Increased continuity and job satisfaction for Body&Fit after switching to Android scanners

Body&Fit is a supplier of sports nutrition, protein, dietary supplements and vitamins, among other products. The company offers support to anyone pursuing a healthier lifestyle. The products that contribute to that healthy life are stored in the Body&Fit distribution center in Heerenveen, from where they are shipped to customers throughout the Netherlands and abroad. Previously, the company used handheld scanners with Windows as the operating system; they have since switched to user-friendly ProGlove MARK scanners and Android scanners from Zebra.

From Windows to Android

When the old scanners needed replacing, Elbert Oudhof, Head of Logistics at Body&Fit, wrote a tender. “Our previous scanners ran on Windows. However, this operating system was no longer supported by Microsoft. Therefore, for the sake of security and continuity, we decided to switch to Android. A logical choice; Android is simply the future. CaptureTech ultimately emerged as the winning supplier. Apart from the attractive price tag, the main reason for going with them was their partnership with software developer Diract IT, supplier of our Warehouse Management System.”

Virtually no more dropouts

By using CaptureTech’s scanners in conjunction with partner Diract IT’s Warehouse Management System (WMS), everything is optimally aligned. The lines between us are short and any hiccups are resolved in no time. Both run on Android, which provides a great deal of continuity. As a result, Oudhof gets a lot of positive feedback from his colleagues in the warehouse. “They have much less downtime. Our old scanners were connected via a plug with a wire. Over time, that plug became somewhat lame, which caused frequent outages. The new scanners work via a Bluetooth connection, so we hardly have any connection loss.”

Efficient and careful

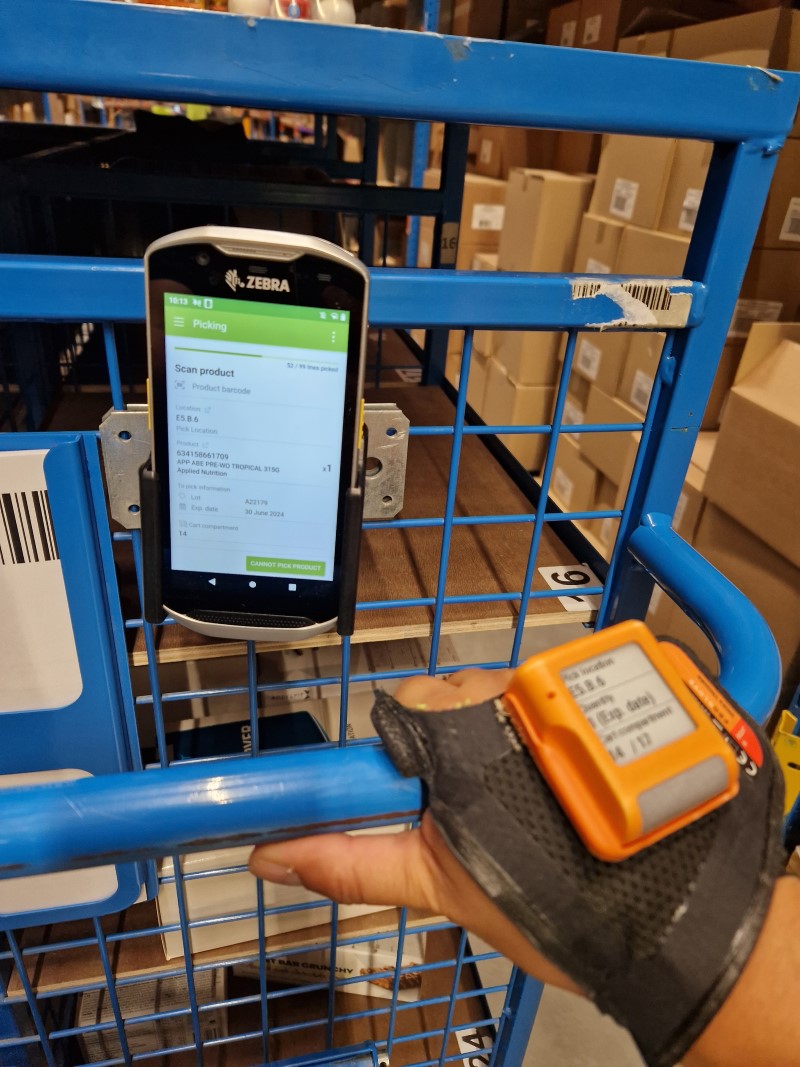

Body&Fit uses a combination of two types of scanners, the Zebra TC52 scanner (it is mounted on the pick cart) and the ProGlove MARK Display. Order pickers are simply directed to the correct picking location, then they scan the barcode of the product to be picked. They easily pick multiple orders simultaneously for different customers in one route (multi-order batch picking). The ProGlove wearable barcode scanner indicates which bin of the picking cart the product should be placed in and the next picking location. Thanks to Diract’s Ceyenne software, carts are filled as optimally as possible. A big improvement in efficiency, accuracy and job satisfaction.

Oudhof also receives positive feedback from employees about the ease of use of the new scanners. “What I mainly get back is that the ProGlove glove is so light that you almost don’t feel it. Quite a difference from the big scanners my colleagues used to wear on their arms. In addition, with the ProGlove they have two hands free for picking, which greatly improves speed. A KPI of 250 products per hour, as it applies to us, can only be achieved with a combination of the right hardware and software. Especially if the average order contains many different products. With our new scanners and Ceyenne WMS from Diract, we almost always achieve two and a half pick carts per hour, something that used to be quite a challenge.”

Everyone’s own glove

As an additional advantage of the ProGloves, Oudhof also cites hygiene. “With the arrival of corona, it was extra important to pay close attention to this. We work in shifts here in the warehouse. Previously, the scanners, often including sweaty tape, passed from shift to shift. Now all warehouse workers have their own glove, which is of course much more hygienic.”

Always up-to-date with CaptureTech Protect

To keep the equipment always up to the latest standards, regular updates must be done. For this purpose, Body&Fit has entered into a service contract with CaptureTech. “Downtime is something we simply cannot use here. CaptureTech Protect ensures that we always have the latest software versions. For this, we don’t have to arrange or monitor anything ourselves. CaptureTech takes care of all this for us. Ideal!”

Sustainability and robotics at Body&Fit

When we ask Oudhof about his plans for the future, he looks primarily to sustainability. “Sustainability is a hot topic. Not only with us, but actually in all other companies and sectors. We are looking en masse for ways of working that contribute to a better environment and that require fewer people. The latter is mainly due to the large personnel shortages that are visible across the board. What we are currently investigating, for example, is the possibility of automating the packing process. This is currently done completely manually. We are also looking at automated alternatives for our picking process. Sounds like future music, but is closer than we think.”

Want to know more about Body&Fit? Then check out their website here.