Digitalization brings Van der Meulen greater efficiency, sustainability and customer satisfaction

Van der Meulen is a wholesaler, importer and distributor of high-quality toys from well-known brands such as LEGO, Clementoni and Miffy.

Van der Meulen is a wholesaler, importer and distributor of high-quality toys from well-known brands such as LEGO, Clementoni and Miffy.

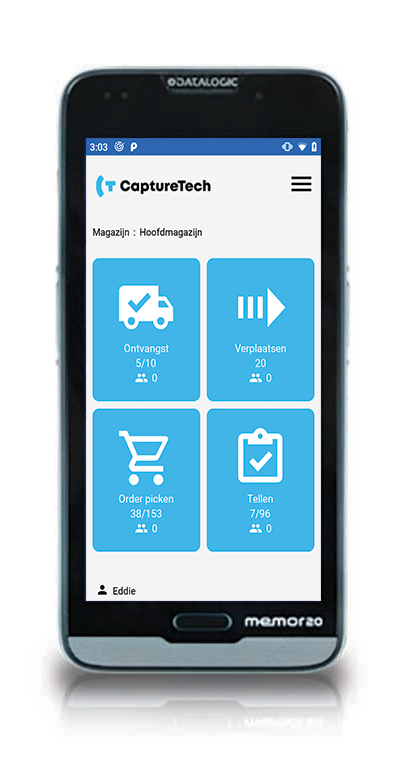

Van der Meulen is a wholesaler, importer and distributor of high-quality toys from well-known brands such as LEGO, Clementoni and Miffy. Until recently, the entire order picking process was manual. In 2021, Van der Meulen requested the help of CaptureTech. Since then, they have been working with Memor 10 handheld scanners from Datalogic and portable ProGlove barcode scanners. In addition, the entire warehouse is equipped with fast and reliable wifi and they have switched to new order picking software. The result? A saving of twenty hours per week in effective order picking time, a significant cost reduction because less flexible labor is needed, and much less paper consumption.

As manager of operations, Anne Bijlsma is closely involved in this automation effort. “In fact, I was the instigator of the whole process,” he says. “We have been supplying toys for 140 years and we have been doing it well for 140 years. Yet it was time for modernization. The immediate reason was moving into a new distribution center that we wanted to use as efficiently as possible. Moreover, our customer base, and thus our orders, are becoming increasingly diverse. Our customers are toy stores, web shops and everything in between. We handle small and also very large orders. Sometimes with many of the same items, but often with many different ones. Quite a complex logistical process. High time for a digital improvement to replace the paper order flow with modern scanning equipment. Not only much more efficient, but also much better for the environment.”

Once it was clear what Van der Meulen’s wishes and requirements were, a tender was issued. Of all the submissions, CaptureTech ultimately emerged as the winner. “They understood from day one how our logistics work and how complex our order flows can be,” says Bijlsma. “The team at CaptureTech immediately came up with applicable solutions. They considered optimal preparation as important as we did, both technically and humanly. There are employees who worked with paper for 15 years and now suddenly had to switch to scanners. You have to prepare and supervise something like that well. CaptureTech got that.

Before Van der Meulen embarked on this journey, nothing had actually been set up in terms of automation; no wifi, no ICT software, no scanners. “Together with CaptureTech, we analyzed our warehouse, during which they listened and thought carefully. A plan was created and rolled out on fairly short notice for the Wi-Fi infrastructure. This was necessary in part to allow the scanners to do their job. In choosing the scanners, all our colleagues in the warehouse were closely involved. After all, they are the ones who have to work with them every day. We took them into a store setting, where they were allowed to test all possible scanners.”

The final choice was a combination of Memor 10 handheld scanners from Datalogic and portable ProGlove barcode scanners. “The big advantage of the ProGlove is that they are quick and easy to use. They fit seamlessly with the warehouse workers’ natural movements during the order picking process. The order pickers also use the Datalogic Memor 10, which provides them with the latest information on both product and sales order in real time. The simplicity and user-friendliness allow our colleagues to focus only on the right things. Thus, they do not receive unnecessary information and can concentrate optimally. Because we involved our employees in the process from day one, the transition from paper to digital was flawless. The user-friendliness of the hardware and the good guidance from CaptureTech also definitely contributed to this.”

The complete implementation was accomplished in one day. “Unique,” Anne believes. “The win, of course, was in good preparation, which made everything run like clockwork that day. And actually it still does, thanks in part to the good integration of CaptureTech Connect with our ERP system Navision. I think it’s a big plus that we were able to buy everything from one party. Not only the hardware and software, but also the WiFi infrastructure. This way everything is optimally coordinated and there can never be ‘finger pointing’ should anything go wrong.”

“We are now six months on and I can only say that we are very satisfied. Even the colleagues who were quite apprehensive about digitization say they never want to go back. It saves them a lot of walking every day because the paper orders no longer have to be picked up. That is a huge efficiency gain. We save about twenty hours a week in order picking time and benefit from a significant cost reduction because fewer temporary workers are needed. Moreover, we achieved a 75 percent reduction in the number of defects already in the first month and also save two hundred packs of paper per year.”

When we ask Bijlsma about his plans for the near future, he says Van der Meulen wants to take the capabilities of CaptureTech Connect even further. “The cloud-based Connect environment is regularly updated, with CaptureTech not only taking our solutions with them, but also those of other Connect users. In this way, they ensure that Connect perfectly matches the requirements from the field and that our processes match Connect again. So for all parties a win-win situation.”

Van der Meulen will also soon start using a new feature that allows the company to take pictures throughout the order process. With this, Bijlsma aims to eliminate final inspection and increase customer satisfaction. They will also soon have the ability to receive composite orders. “Given the complexity of our inbound goods flow, this is a very big efficiency gain for us. Expectations are high!”

Visit www.vandermeulen.com for more information.